About the project

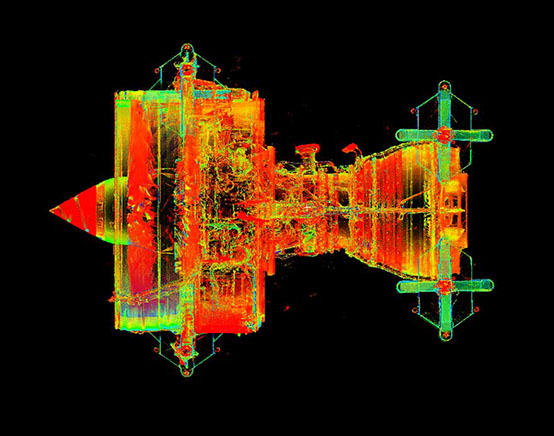

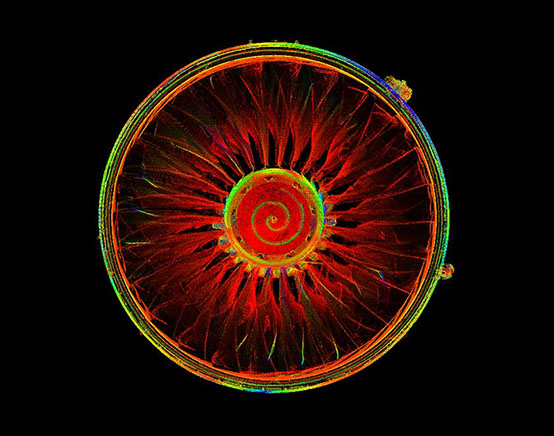

Jet engines are routinely serviced and maintained. With each engine costing millions of pounds, itís important that the engine is back in the air as quickly as possible. The engineers working on the engines have to be both fast and efficient.The size of the engines and the stands they are placed on can cause issues when trying to work closely on the components. Elevated platforms can be used but they have to avoid contact with the engine whilst getting the engineers close enough to carry out their task.Our scope was to scan the engines, sometimes attached and sometimes detached from the aircraft and provide the data in order to design bespoke platforms to enable work to be carried out efficiently whilst also reducing the potential of contact between platform and engine.

- The engines are usually only available for a very short period of time to allow for the service which meant we only had a small window to scan.

- The speed of the scanning ensured the engineers didnít fall behind schedule with the planned maintenance.

- Multiple engines have been scanned as each type of engine is slightly different and needs a different platform configuration.